This post breaks down the real world differences between NPTand G-thread (BSPP), why flush diaphragm transmitters shouldn’t be NPT, and the gotchas that can wreck a perfectly good install.

- - - -

This post breaks down the real world differences between NPTand G-thread (BSPP), why flush diaphragm transmitters shouldn’t be NPT, and the gotchas that can wreck a perfectly good install.

- - - -

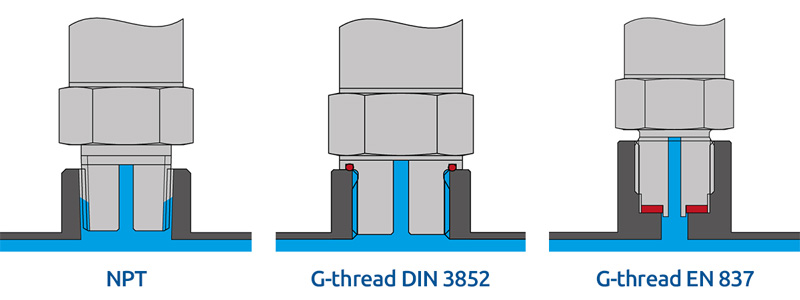

Translation: NPT = thread seal. G thread = face/shoulder seal. They are not interchangeable.

- - - -

NPT is everywhere in legacy North American piping. It’s simple and rugged, but two realities bite engineers:

We offer 1/2 14 NPT and 1/4 18 NPT options on many non flush BD SENSORS transmitters for plants standardized on NPT. But when media or hygiene demands a flush diaphragm, NPT is not the move (see below).

- - - -

G-thread’s parallel geometry means you’re not wedging a taper to seal—you’re compressing a gasket/O-ring against a defined metal face or shoulder. That gives you:

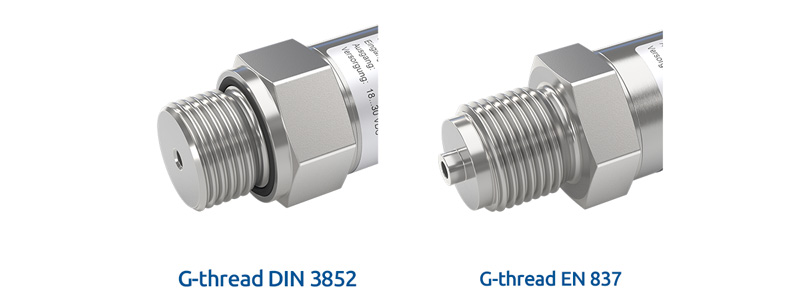

In our catalog you’ll see G1/2 and G1/4 offered as either EN 837 (flat-face + gasket) or DIN 3852 (Form A/B). Functionally both are BSPP threads; the difference is where and how the seal happens.

- - - -

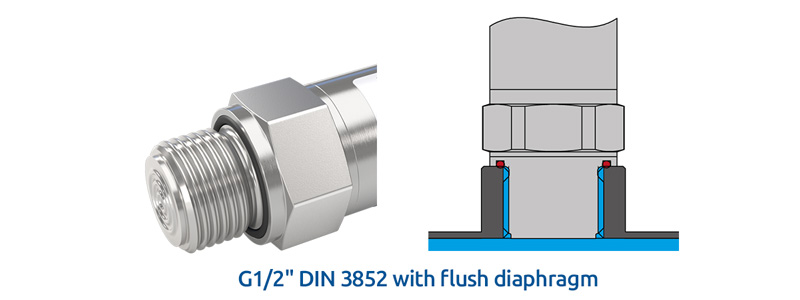

A flush-diaphragm transmitter places the sensing element right at the tip to avoid pockets that clog with viscous or crystallizing media. That design doesn’t play well with NPT’s thread seal:

Bottom line: Flush designs need a shoulder sealing interface like the G-thread DIN 3852 (sealing ring/O-ring). That’s why we don’t pair flush diaphragms with NPT.

- - - -

We get this question weekly: “G1/2 is the same size as 1/2 NPT, right?” Not quite.

Use the correct adapter if your plant hardware and sensor standard don’t match.

- - - -

- - - -

- - - -

Send us your port drawing or a clear photo. We’ll confirm the standard and recommend the correct BD SENSORS part number and sealing kit.

info@bdsensors.us or call 678-556-5634

5150 Stilesboro Road

Suite 430

Kennesaw, GA 30152

USA

Tel +1 678-556-5642

E-Mail: info@bdsensors.us

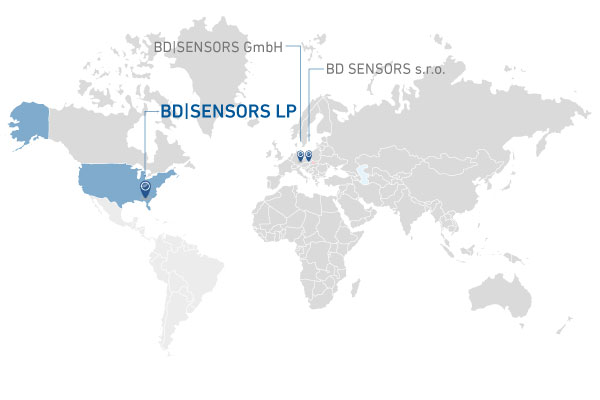

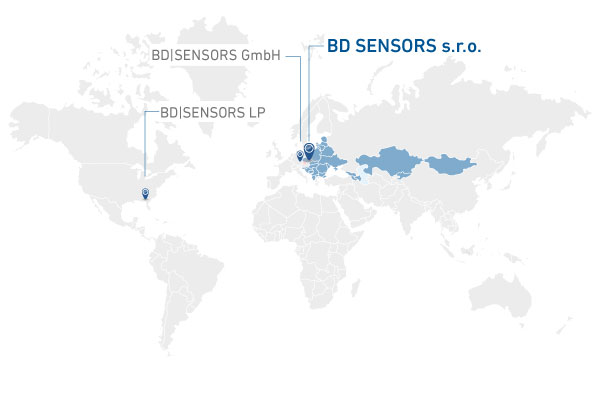

We are a globally operating company group with the two sister companies BD|SENSORS GmbH (Sales Worldwide) and

BD SENSORS sro (Sales Eastern Europe). Here you will find all contact options at a glance:

BD|SENSORS GmbH

BD-Sensors-Str. 1

D-95199 Thierstein

Germany

Tel.: +49 (0)9235 / 9811-0

Fax: +49 (0)9235 / 9811-11

BD|SENSORS LP

5150 Stilesboro Road

Suite 430

Kennesaw, GA 30152

USA

Phone +1 678-556-5642

info@bdsensors.us

www.bdsensors.us

BD|SENSORS LP

Available languages website

![]() English

English

BD SENSORS s.r.o.

Hradišťská 817

687 08 Buchlovice

Tschechische Republik

Tel.: +420 572 411 011

Fax: +420 572 411 497