The truth is that most pressure measurement problems fall into a handful of categories.

If you understand these challenges and know how to address them, you can dramatically improve system reliability and reduce costly downtime. In this article, we’ll examine the five most common problems engineers face with pressure transmitters, and explore how they can be solved with the right technology and best practices.

Problem 1: Drift and Loss of Accuracy

Every transmitter is designed to meet a certain accuracy specification, but over time, environmental stress and sensor fatigue can cause readings to drift. This drift may start small — a few percentage points off zero — but in industries like chemical processing or food production, even small deviations can create big problems.

One real-world example comes from an automotive manufacturing plant in the Southeast U.S. Their coating line relied on accurate pressure measurement to control paint spray. But over the course of several weeks, their older transmitters began to show gradual drift. Operators had to recalibrate them weekly, costing valuable production time.

When they switched to BD|SENSORS DMK 351P series transmitters, the long-term stability of the sensors reduced the recalibration frequency. Instead of weekly adjustments, calibration checks were pushed to once every three months. The savings in maintenance hours alone justified the upgrade, not to mention the improved quality of their coatings.

The Solution:

• Choose transmitters designed with long-term stability in mind.

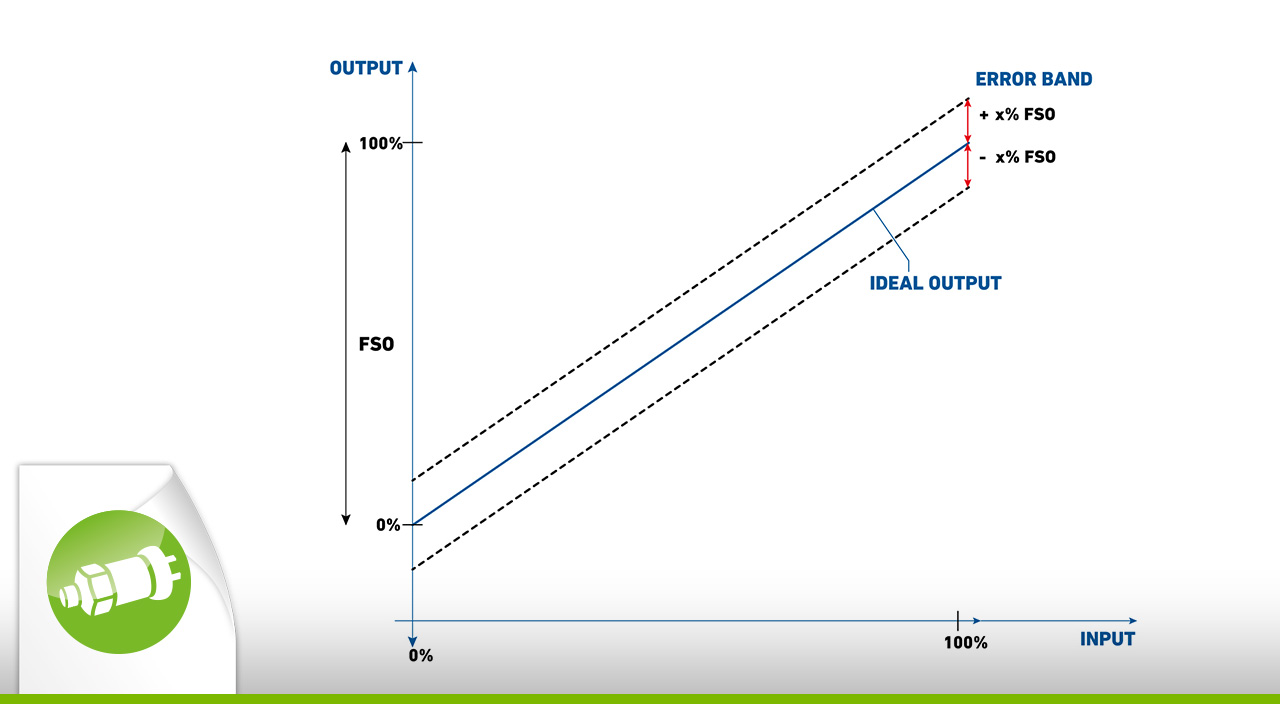

• Select models rated at 0.25% FSO or better, depending on process needs.

• Implement scheduled calibration but extend intervals as stability proves itself.

_ _ _ _ _

Problem 2: Overpressure and Sensor Damage

In many systems, pressure spikes are unavoidable. A pump startup, a closed valve, or a sudden line blockage can send a shockwave of pressure through the system. If a transmitter is not built to handle those spikes, the diaphragm can deform permanently, leading to inaccurate readings or total failure.

This was the case for an oil and gas operator working with injection lines. Their legacy transmitters failed repeatedly during startup sequences. Each failure meant pulling equipment offline, often during critical operations.

The solution was to install transmitters with stainless steel thinfilm sensing elements from BD SENSORS. Stainless Steel thinfilm diaphragms are inherently resistant to overpressure and can withstand temporary spikes without permanent deformation. After switching, the operator saw a dramatic drop in sensor failures, improving uptime and reliability.

The Solution:

• Use transmitters rated for overpressure protection when spikes are likely.

• In hydraulic or high-pressure applications, stainless steel may be preferable.

_ _ _ _ _

Problem 3: Electrical Interference and Signal Noise

Modern plants are packed with variable frequency drives, high-voltage equipment, and communication networks. All of this can introduce electrical noise into sensitive analog signals like those coming from pressure transmitters. The result? Unstable readings that make no sense to operators or control systems.

An electronics manufacturer faced this issue in their cleanroom facility. Despite pristine process conditions, their pressure monitoring system reported erratic values. After investigation, it became clear that nearby power equipment was introducing interference into the signal wiring.

By switching to BD SENSORS transmitters with robust EMC (electromagnetic compatibility) protection, along with shielded cabling and proper grounding, the noise disappeared. The clean, stable signals allowed the facility to maintain the tight environmental controls required for semiconductor production.

The Solution:

• Select transmitters with high EMC resistance.

• 4-20mA 2-wire output are less sensitive than a voltage signal

• Use shielded cabling and proper grounding.

• Where possible, route signal wiring away from high-voltage equipment.

_ _ _ _ _

Problem 4: Media Compatibility Failures

Not all fluids and gases play nice with all materials. Stainless steel, while versatile, is not immune to corrosion. Aggressive chemicals, salty wastewater, or even some cleaning agents can attack sensor diaphragms. Once corrosion begins, accuracy is compromised, and failure is only a matter of time.

A dairy producer encountered this when cleaning solutions began corroding the stainless steel diaphragms of their transmitters. The result was frequent replacements and the risk of contamination. By shifting to ceramic-based transmitters with a 99.9% purity, which resist both aggressive chemicals and cleaning agents, they eliminated the problem.

The Solution:

• Always match wetted parts to process media.

• For aggressive or corrosive fluids, ceramic elements are often superior.

• Always check compatibility of all media wetted components (diaphragm, sealing, process connection).

_ _ _ _ _

Problem 5: Harsh Environmental Conditions

Even when the process media is not extreme, the operating environment can be. Mining, marine, and outdoor energy applications subject transmitters to vibration, dust, moisture, and temperature swings. In such conditions, even a well-specified transmitter can fail prematurely if not properly protected.

A mining operation was struggled with transmitters failing due to dust intrusion and vibration on haul trucks. By upgrading to BD SENSORS transmitters with IP-rated housings and vibration-resistant construction, they finally achieved the service life they needed. Maintenance intervals were extended, and operators could trust the readings even in harsh conditions.

The Solution:

• Choose transmitters with appropriate IP protection ratings.

• Ensure vibration resistance for mobile or heavy equipment.

• IP67/68/69K rating and potted special versions increase resistance against vibrations and condensation.

• Consider cable versus connector designs depending on environmental sealing needs.

_ _ _ _ _

How to Prevent These Problems Altogether

While each of these five problems is common, they are not inevitable. Most failures trace back to one of two root causes: selecting the wrong transmitter for the application, or underestimating the stresses the transmitter will face over time.

Working with a supplier like BD SENSORS LP helps engineers avoid these pitfalls. With both ceramic and stainless steel technologies, configurable ranges, and robust design options, BD SENSORS products can be tailored to fit the exact needs of a system. The result is fewer surprises in the field and longer service life across the board.

_ _ _ _ _

Conclusion

Pressure transmitters are critical to safe, efficient, and reliable operations. Yet too often, they are treated as commodity components, selected with little thought. The reality is that choosing wisely at the start can prevent many of the most common problems engineers face: drift, overpressure, electrical interference, media compatibility issues, and environmental challenges.

By learning from real-world cases and applying best practices, engineers can transform pressure measurement from a weak point into a strength. And by working with a manufacturer like BD SENSORS, they gain access to the technology and expertise needed to match the right transmitter to the right job.

If you’re facing persistent pressure measurement problems, the solution isn’t more recalibration or frequent replacements - it’s a better transmitter from the start.

Contact BD SENSORS LP today to discuss how to put these problems behind you.